Quick update!

I have been super busy on the Yamaha project, but I have been working on a few small bits for the CR:

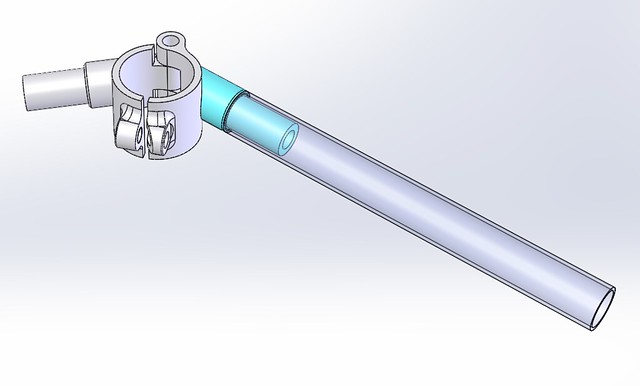

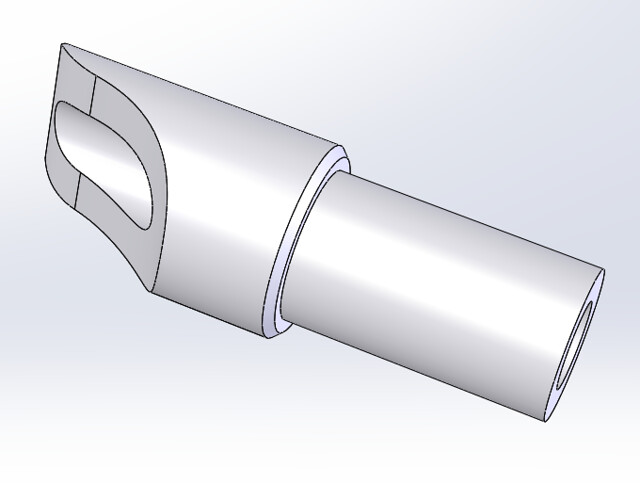

I have been working on a few small details, after seeing the CR750 over at the Manx, I decided that a custom throttle was in need. A dual-action push and pull throttle housing which looks "original" with the correct fastenings and adjusters. I have modelled this up in CAD, and will post some images shortly. I will most probably utilise an original or new throttle tube and will machine the other parts.

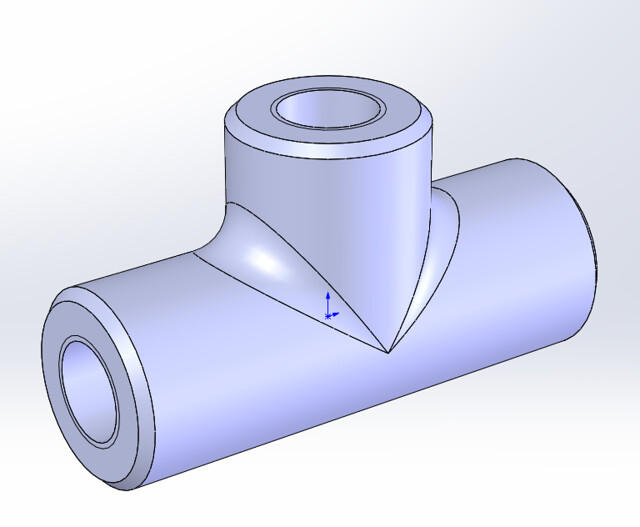

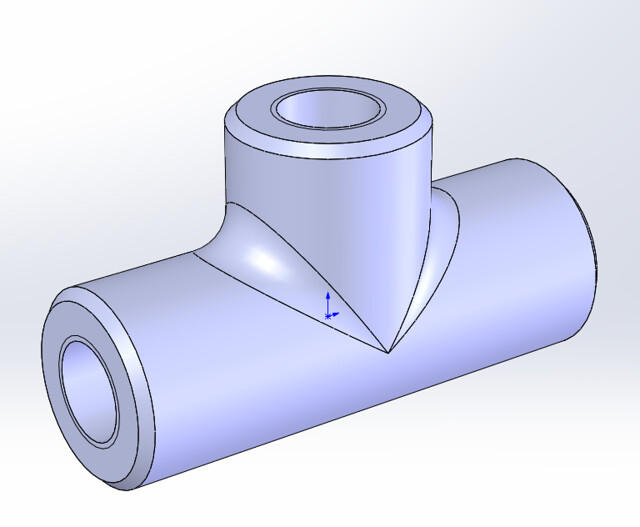

I have also been playing with the front brake splitter, this will be held on with a wire clip and a steel plate bracket. The T will be machined from solid aluminium, and the bracket and wire will be fabricated.

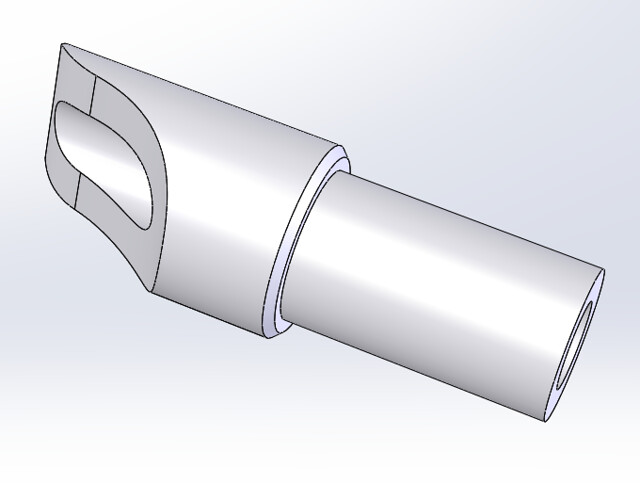

Another small detail is the works style fuel tap. Managed to get a starting point CAD model online, and to be honest the original design is pretty rubbish in terms of sealing. I think I will produce a version that looks like the original but has internals that won't leak! The TZ taps were pretty known for leaking as well

Here is the fuel tap body:

Anyway I wanted to test out some new technology, casting is something that has always fascinated me, I think it's the history around the process, and how good it can be as a production method. Loss wax casting, is where a wax model or plug is made of the intended shape, this is buried in sand or plaster with a vent and a sprue. When the molten aluminium is poured into the sprue hole the wax melts away allowing the aluminium to fill the cavity. This is a common method of casting relatively low volume parts.

However the difficulty and repeatability issues come when producing the plug from wax as you need a mould to create this plug.

3D printing technologies are moving on at quite a pace, and it's something that I am involved with on a daily basis, both designing and having parts 3D printed. A new material has recently been released which is a "castable" resin so I thought I would give it a try!

Here is the part as it has come out of the printer, you can see a "raft" the 2D shape on the table, and the "supports" the random pillars holding the object up. The raft and supports are removed leaving the plug.

The plan is to bury this model in plaster, leaving a vent and a sprue. This can then be cast for, or burnt out and cast from.

Of course after the casting process a lot of the surfaces would have to be post-machined to give suitable surface finishes for sealing and interfacing with other parts. And in reality the cast part would have holes blanked off, however for this stage I am interested to see what resolution is possible to get from a plaster casting.

Progress to come at a later date on the fuel tap front.

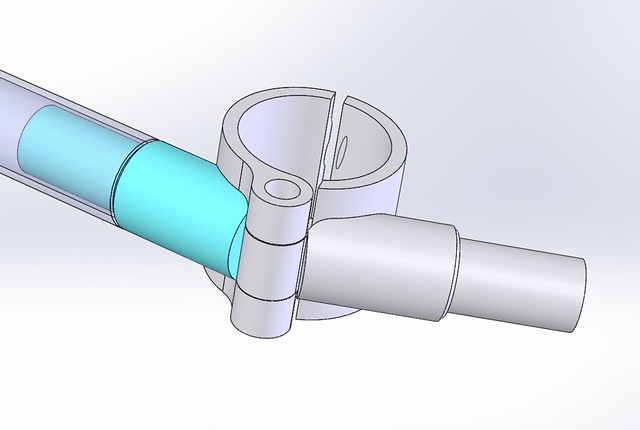

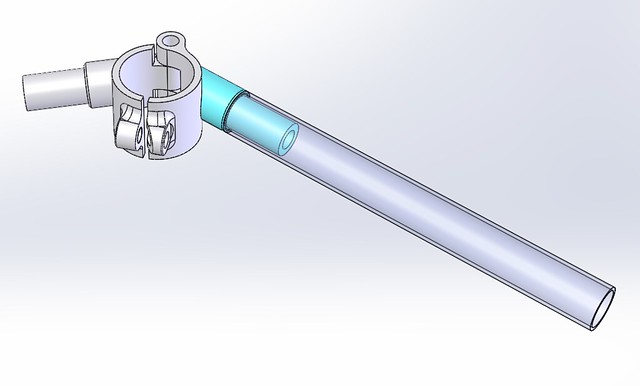

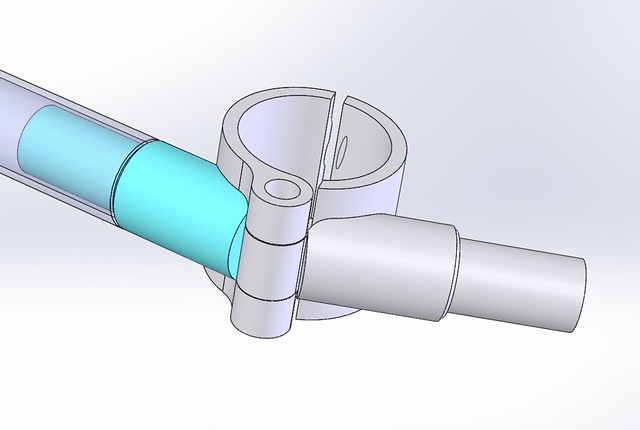

I have also made a small amount of progress on the clip-ons: tube interface parts being machined at the moment:

Due to the complex curvature, this part will start off as a piece of EN8 bar, will be CNC turned, and then added to the 4th axis of a Mill to 3D machine the complex geometry.

This enables the tube to be set at a repeatable angle, compared to the boss each time, this also gives a good engagement sleeve for the length of handlebar tube.

Cheers

CR21

Can't find a company that will do a small amount, everyone that has the correct CNC only do large orders.