hi all

well finally got the front wheel hub sorted and that is off to get spokes and rim laced and new tyre fitted ( dont trust myself on this one )

now questions on rear wheel , firstly... front wheel had to drill the indents out on retainer, is this the same on rear ? i e are these staked ( if so how big to drill and how deep to go )

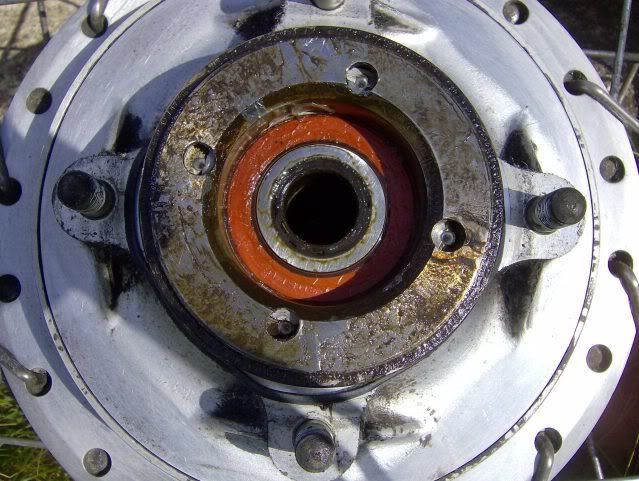

pic attatched if you look closely you can see punch marks in the 4 holes ?

also is this a right hand thread ie turn right to unscrew

lastly brake linings look new but on drum very light surface rust has started to appear can i remove this rust myself or would it need any professional work done to it